Avoiding Downtime

Continuous operation is essential to maximise return on investment in pulp and paper mills. For economical running, maintenance costs must be minimised throughout the plants, requiring engineering skill and reliable components so that shutdowns can be scheduled.

The Process

In particular the heart of the process, the digester in the pulp mill and the paper or board machine in the paper mill, must always run as first priority.

Unscheduled shutdowns must be avoided, primarily to avoid production loss but also to minimise maintenance costs.

Keeping energy consumption low is also an important factor in running an economical plant, affecting many aspects of process flow and component selection. Compliance with environmental performance legislation is an increasing and vital priority.

Benefits when Working with Densit

Densit® wear protection systems is a useful tool in the ongoing battle for continuous improvement and minimum operating costs. Reliable wear linings are essential for effective maintenance planning, and a Densit® solution offers both reliability and long life: less frequent planned maintenance and no unscheduled maintenance.

Densit® wear protection systems can be designed to minimise heat loss in components, ducts and pipes.

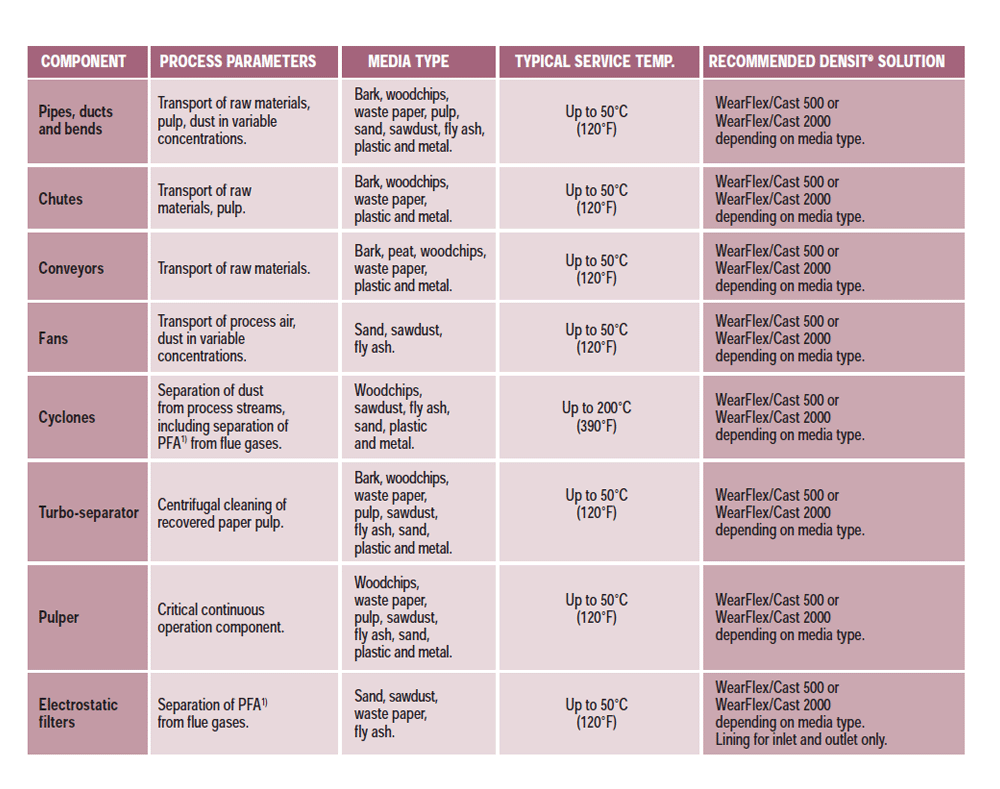

Densit Process Flow

This is the typical process flow in the cement industry, showing components where Densit wear- resistant lining solutions are installed

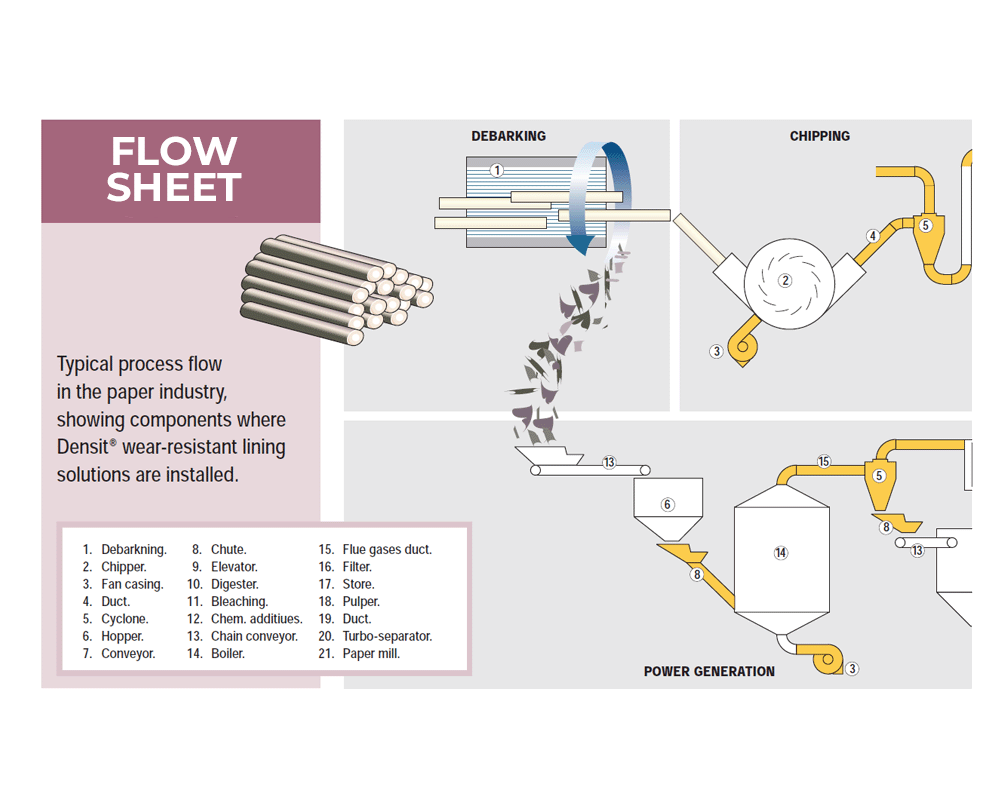

Components list

Find below the table that shows components, their process parameters . We also provide what solution is recommended is by Densit.

Components list

Find below the table that shows components, their process parameters . We also provide what solution is recommended is by Densit.